PRINTED CIRCUITS FOR FLEXIBLE HYBRID ELECTRONICS

Printed electronics often involve touch applications on flexible transparent films, which creates a demand for transparent conductive materials. Integration of ICs enables the control of capacitive touch functionality, combined with serial communication protocols such as I2C or USB. This allows for much smaller and more efficient connections than traditional solutions using bulky cables. DoMicro is capable of making Flexible Hybrid Electronic touch applications with screen-printed transparent PEDOT electrodes, inkjet printed silver circuitry and Anisotropic Conductive Adhesive (ACA) bonded components. This paper focusses on the integration processes of printed transparent conductive polymer polyethylene dioxythiophene (PEDOT:PSS).

Human machine interfaces and control displays should be easy to understand for the operator. Highlighting essential information depending on mode or status of the equipment creates a focussed and minimal atmosphere without distraction. Visual appearance and coloured feedback of touch icons by RGB controlled backlight LED’s is featured by transparent capacitive touch technology in Flexible Hybrid Electronics (FHE) circuitry. A FHE-Touch foil integrated with a FPCA-LED assembly enables a fully flat, flexible interface system that can be integrated in curve products and surfaces. Touch icon buttons can be completely hidden or made invisible when backlight is switched off.

Figure 1 – User interface by Metafas

Application demonstrator

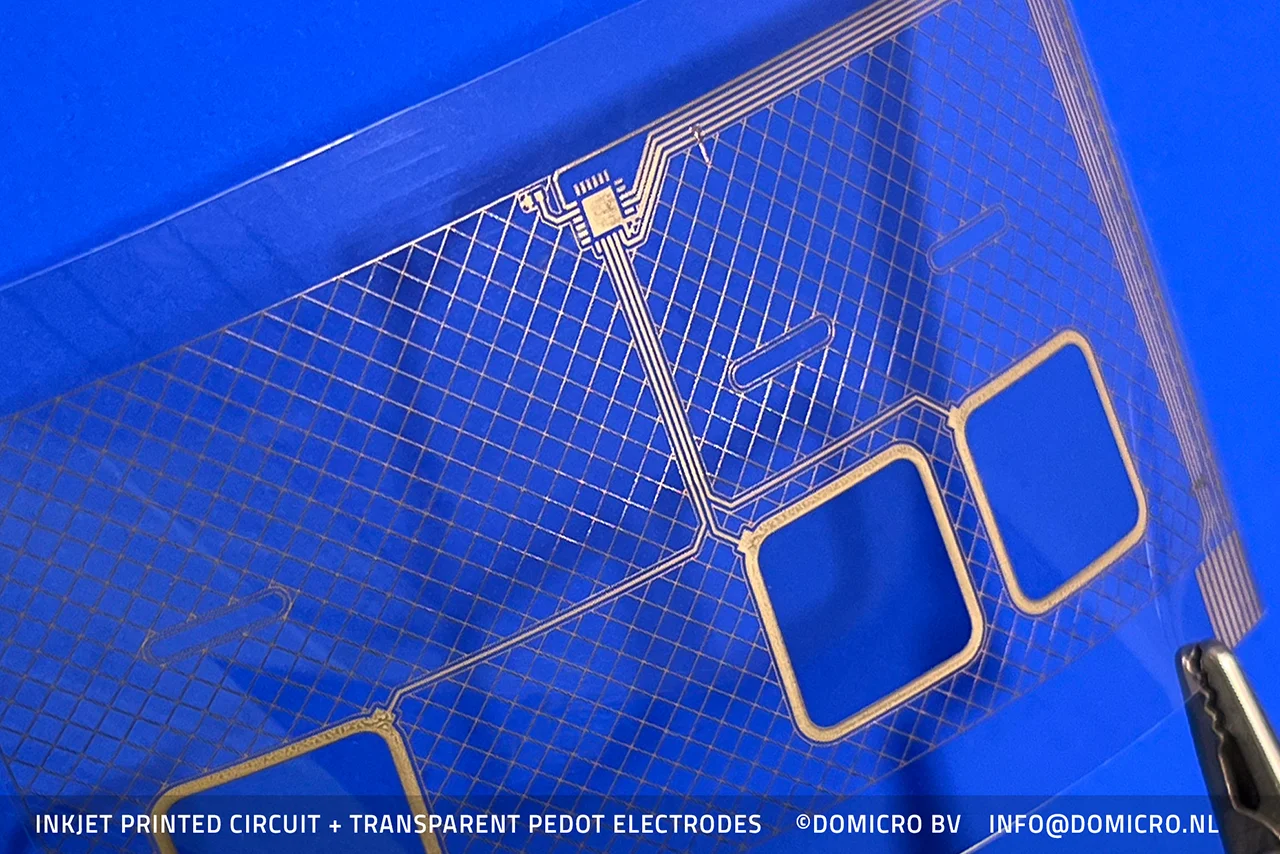

Figure 1 shows a user interface with capacitive touch buttons to use with backlighting. The FHE module is placed on top of a flexible FPC with RGB-LEDs that will respond to the touch actuation. The product is made by a combination of screen-printed PEDOT touch electrodes and inkjet printed silver traces. The transparency of PEDOT electrodes allows for the backlighting and lightguide. Figure 2 shows this transparency of the blueish PEDOT electrodes printed on a PEN film.

Figure 2

The transparency and conductivity of the PEDOT electrodes depends on the layer thickness. This sample has a PEDOT layer of only 350 nm thickness. This results in a sheet resistance of 320 Ω/sq. The PEDOT screen-printing paste is commercially available. DoMicro is capable to screen print on films up to 150×150 mm on the Aurel C1010 screen-printer. Metafas screen prints series up to 1,000 pieces on 1,000×700 mm.

Around the PEDOT electrodes the electrical circuit is printed with a silver nanoparticle (NP) ink. This circuit is shown in figure 3. The inkjet printing technology allows for small contact pads to interconnect the QFN packaged driver IC. This IC has pad sizes of 250 µm at a pitch of 500 µm. Using this inkjet printing technology, DoMicro is capable of printing at a pitch down to 100 µm. The inkjet printed circuit is a 2-layer circuit with inkjet printed insulator to separate crossing top and bottom silver traces. For this inkjet printing process the SUSS MicroTec PiXDRO LP-50 inkjet printer is used. Both the UV curable insulator ink and silver ink are commercially available. Sintering of the NP is performed in a box oven at 150°C for 30 min.

Figure 3

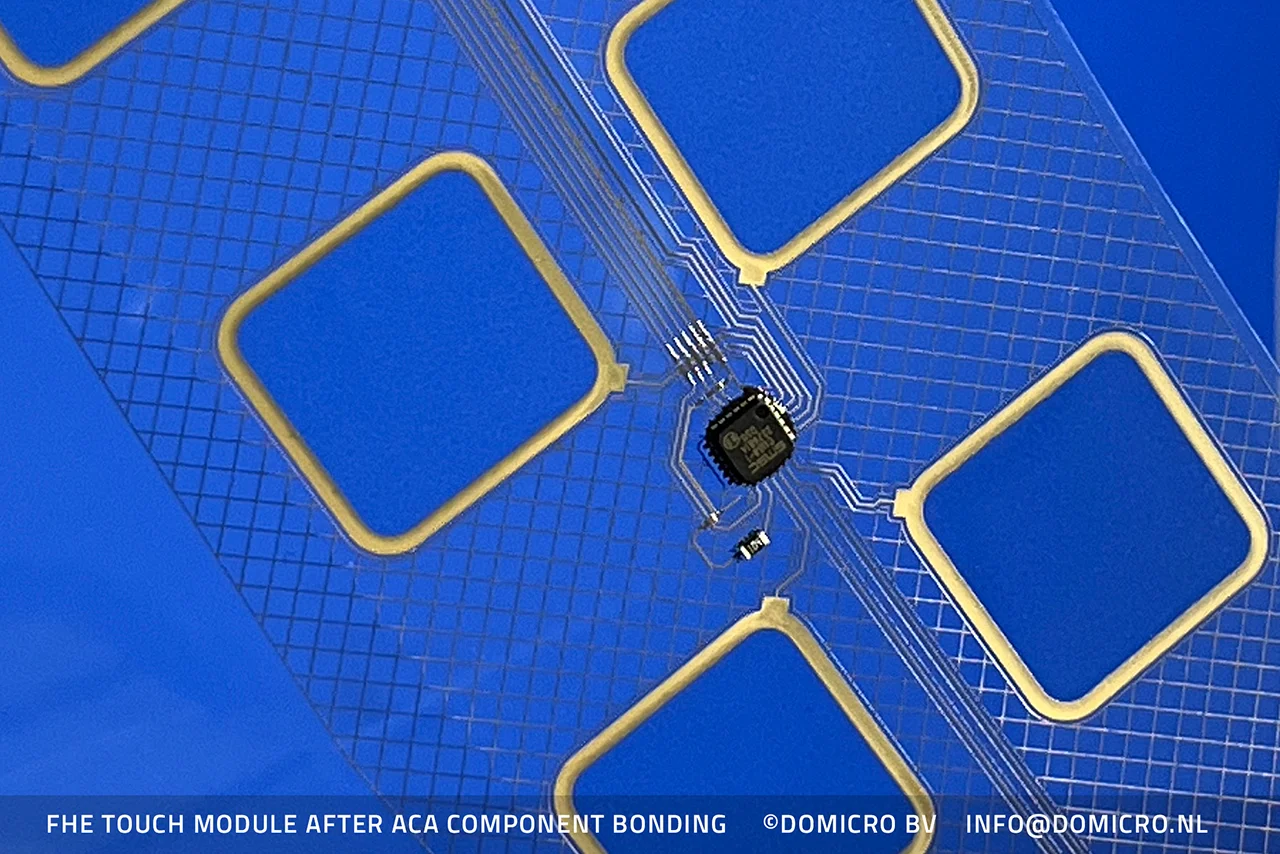

The PEN substrate and silver circuit do not allow for a standard soldering process for integration of components. An ACA is used to make a thermocompression bond between the IC and passive components and the printed circuit. Figure 4 shows an FHE touch module after assembly of the components. The Pick&Place process is performed with a Fineplacer Pico having an alignment accuracy of 5µm.

Figure 4

The FHE touch module can, for example, be connected to a flexible LED FPC, such as shown in Figure 1. This interconnection is achieved using ACA through a thermocompression bonding process. The process, carried out with the Fineplacer PICO, enables strong and reliable interconnections at relatively low bonding temperatures of around 160 °C. These bonds ensure high reliability without short circuits, while preserving the flexibility of the transparent printed electronics touch circuit in combination with the LED FPC.

Conclusions and outlook

Screen-printed electrodes with transparent conductive polymer PEDOT are useful for touch applications in combination with backlight. The presented process steps show how such FHE touch modules could be made. Many designs of these touch button circuits are possible. Besides FHE modules with touch buttons, this printing process also allows for other transparent touch applications, e.g. trackpads or touch screens. DoMicro can support the technology for manufacturing as well as the hardware and system integration. Metafas complements this by bridging the gap towards industrial scalability and manufacturability.

STRONG COLLABORATION

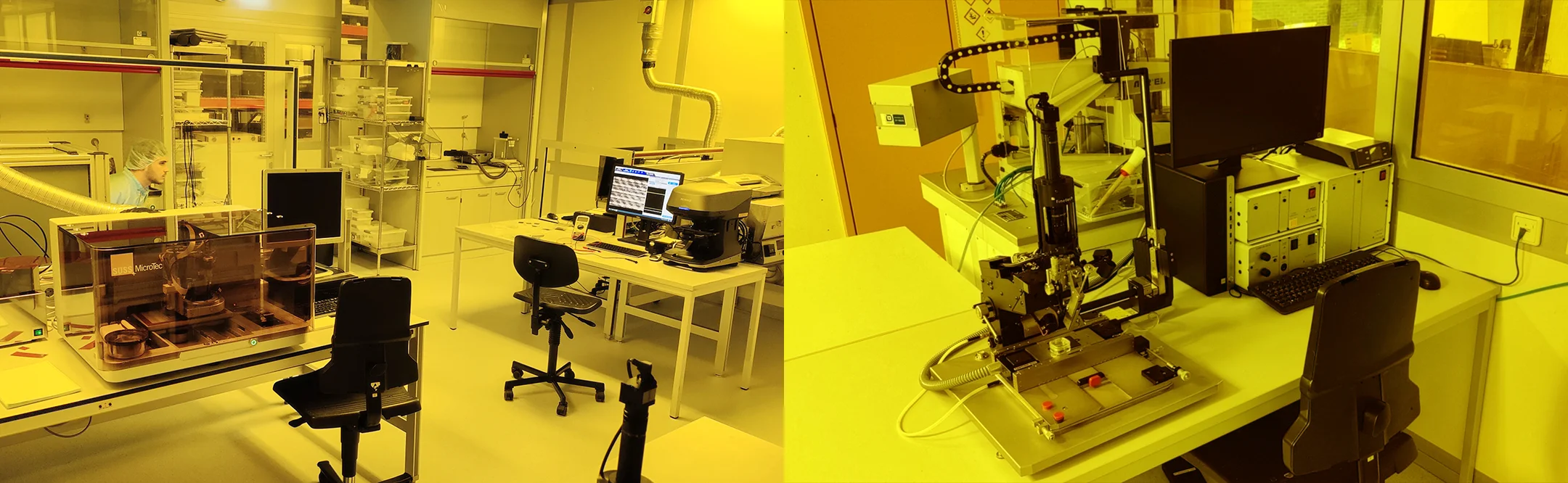

DoMicro and Metafas have collaborated for many years, supported by their close geographical proximity. DoMicro develops advanced inkjet printing processes and technology for micro assembly and 3D packaging of FHE and micro devices. While DoMicro focuses on R&D and prototyping with transparent PEDOT electrodes, inkjet-printed circuitry, and micro-assembly, Metafas transforms these innovations into reliable products. With expertise in membrane switches, printed electronics, and advanced foil-based HMI applications, Metafas develops and produces small and medium series using advanced techniques.

By combining the capabilities of DoMicro and Metafas, high-performance devices can be made, pushing the boundaries of flexible hybrid and printed electronics.

IMAGINE, CREATE, ACCOMPLISH

DoMicro provides R&D services, small series production, system architecture and project management. Typically for customers exploring new technologies for circuitry on flexible substrates like transparent conductive films, OPV electrodes, OLED, Lab-on-chip, wearables, in-mould electronics, IC and MEMS integrations.

Metafas operates a fully automated INO screen printing line for advanced printed electronics, using in-house screen fabrication and product finishing. A structured product and process launch system enables FHE technologies – such as transparent PEDOT-based HMI foils – to evolve into volume production for industrial, medical, and consumer applications.

If you are challenged by the market and looking for a partner to move your ideas into realization, contact us. We really do IMAGINE, CREATE AND ACCOMPLISH.